Marine Group Boat Works announces multi-million modernization project at San Diego Bay facility

Marine Group Boat Works Invests in State-of-the-Art Equipment, Modernization of Shipyard Facility on San Diego Bay.

CHULA VISTA, CALIF. – Marine Group Boat Works (MGBW) announced that it will undertake a multi-million modernization project at its 15-acre shipbuilding and repair facility on San Diego Bay in Chula Vista. Central to the project will be the addition of a new state-of-the-art mobile boat lift, which will be the only sideways-crawling travelift on the West Coast and the largest in the United States.

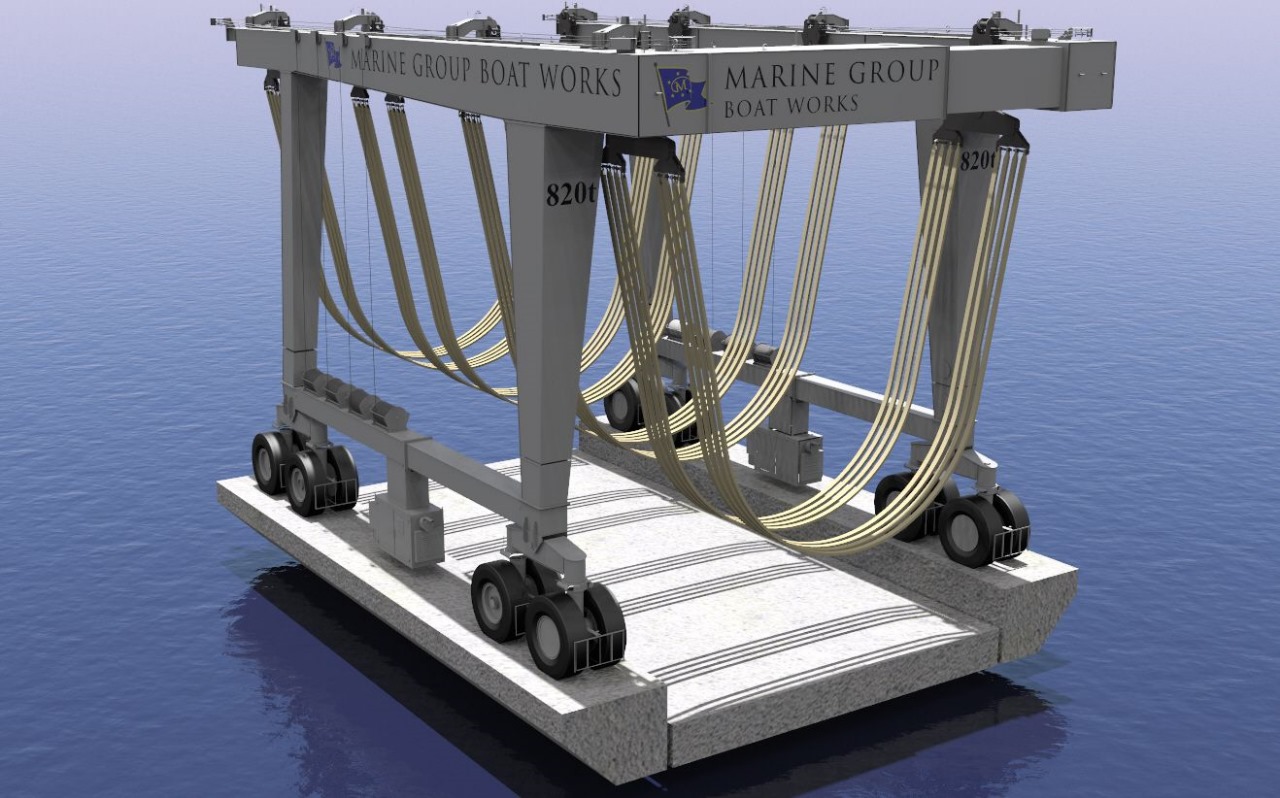

MGBW has contracted with Cimolai Technology, based in Veneto, Italy, to custom-build a new 820-Ton Mobile Telescopic Boat Hoist that will combine two critical benefits – mega-capacity and flexibility. The giant lift will be able to haul a superyacht out of the water and transport it forward, backward and even sideways on wheels that can turn 90 degrees. Another key feature of the machine is its variable-width, which will allow the crane to expand up to 18.5 feet or collapse for vessels with smaller beams. The incredibly powerful machine will also include a Tier 4 low-emission power source.

The new versatility provided by the lift will allow MGBW to make more efficient use of its one-million-square-foot facility by optimizing the space between vessels when blocked on shore. The build-out is expected to take 12 months, with delivery in Fall 2024.

This is the second major investment in expandable lift equipment MGBW has made in 2023. In April, the firm announced it had purchased a 75-Ton Marine Travelift to increase capacity at its yacht repair and dry-dock facility in Los Cabos, Mexico. MGBW was among the first shipyard facilities in Mexico to experiment with this innovative new design. The investment has allowed the company to overcome previous space constraints and meet increased demand for repairs in the region. Now, MGBW is bringing this proven concept to San Diego – but on a much larger scale.

Why Flexibility is Key

The high-capacity lifts needed to haul out large vessels like superyachts typically take up a large amount of valuable real estate within a shipyard. When vessels are blocked in the yard, the spacing between them is determined by the overall width of the lift, not the boats themselves. With standard boat lifts, the width is fixed, locking the operators into a larger footprint even when it is not required for a specific craft. This wasted space results in lost dry-docking capacity for the shipyard, which in turn creates a backlog of boats waiting for an open slot, significant schedule disruptions (particularly in the busy off-season), and work being turned away.

When the 820-ton lift arrives at MGBW in San Diego, it will be one of the largest and most innovative machines in the U.S. market. It will replace a 660-Ton Marine Travelift that MGBW purchased in 2007, which was featured on The History Channel’s “Modern Marvels” series as the single largest lift of its kind at the time.

Modernization & Sustainability

Plans for MGBW’s boatyard modernization project are currently in environmental review in accordance with the California Environmental Quality Act (CEQA). In addition to the new boat lift, the construction project will include the largest solar panel installation on the San Diego waterfront, which will provide 500 kilowatts of renewable energy to power yard equipment and supply shore-power to docked boats. The project will also include the replacement and reconfiguration of all docks and dredging to restore deep-water access.

The modernization project supports MGBW’s ongoing commitment to environmental sustainability, including lowering craft emissions and reducing noise on the Chula Vista waterfront. The facility will remain fully operational during construction, which is expected to take 10 months.

Earlier this year, MGBW was awarded a Small Shipyard Grant worth more than $1.1 million from the U.S. Department of Transportation’s Maritime Administration (MARAD). The grants aim to help shipyards modernize, increase productivity and expand local job opportunities.

MGBW shares the Port of San Diego’s goal of being a zero-emissions boatyard and continues to lead the industry in sustainable boat repair and construction. In 2022, the company repowered its biggest and most important piece of equipment, the 665-Ton Travelift, with Tier 4 engines, which exceed state and national diesel engine emissions standards. The upgrade made MGBW’s boat lift the most environmentally friendly in the world. MGBW’s entire facility is 100 percent stormwater contained, with not a drop of used water entering the bay. Additionally, MBGW runs a robust recycling program and approximately 85 percent of its fleet of vehicles, forklifts and manlifts are electric-powered.

Economic Impact

The new 820-Ton Lift and modernization efforts will allow MGBW to work more efficiently within its existing footprint by working on additional boats simultaneously, and consequently, enable the company to have an even larger impact on the local economy.

Founded in 1986, MGBW is a full-service marine facility with one of the largest hauling capacities on the West Coast and an industry-leading workforce that provides construction, repair and refit services with a focus on modern efficiency and environmental responsibility.

Since redeveloping the boatyard in 2007, MGBW has grown from 25 local employees to approximately 200 highly skilled team members today. It is the only yard in the world with a specialized team of boatbuilders and refitters that are cross-trained to service a variety of vessels, from tugboats to patrol crafts to mega-yachts.

MGBW is recognized worldwide as the premier super-yacht refit facility on the West Coast, with approximately one-third of its business devoted to this sector. Another one-third is comprised of commercial vessels (including ferries, tugboats, barges, workboats and research vessels), with the final third focused on ship-building and repairs for the U.S. military and other governmental agencies. As of 2023, more than 30 vessels around the world were built by MGBW, with contracts totaling more than $100 million.

Industry Insights

The global superyacht industry is valued at over $35.9 billion, supporting over 6,000 companies, roughly 260,000 jobs and an economic contribution equivalent to nearly half of the entire cruise line industry. While superyachts are large (generally between 120 and 200 feet long), the businesses they support are mostly small. Approximately 80 percent of superyacht businesses have fewer than 80 employees.

According to the U.S. Superyacht Association, big boats also mean big business for the local economy. Just one 180-foot vessel generates over $4 million in expenditures each year, including $1.4 million in maintenance and repairs, $400,000 in fuel, $350,000 in dockage and port fees, $110,000 in food and beverage provisioning, and $250,000 injected into the local economy by guests and crew.

In a 2021 report titled “Economic Importance of the U.S. Shipbuilding and Repairing Industry,” the U.S. DoT MARAD found that every dollar’s worth of goods and services spent leads to another $3.48 in the wider economy.

MGBW estimates its local economic impact at $1.2 billion in the last five years (2018-2022). In 2022 alone, the company spent more than $4.7 million with Chula Vista-based businesses and an additional $2.3 million with businesses in the greater South Bay region.